All About Stribling Design Woodworks

Stribling

Design

Woodworks

is

a

small,

one

man

shop

specializing

in

custom

designed

and

fabricated

furniture

and

fine

woodworking.

Although

some

designs

have

been

created

in

limited

production

runs,

the

bulk

of

my

business

comes

from

customers

who

require

custom,

one-of-a-kind

pieces.

Designed

and

handcrafted

to

meet

the needs and tastes of each client, the finished products have become treasured, first generation heirlooms.

Since

my

first

commissioned

piece

in

1977,

woodworking

had

been

a

part

time

venture,

until

1988

when

the

volume

of

orders

enabled

me

to

design

and

build

custom

furniture

full

time.

Mostly

self-taught

through

books,

magazines

and

trial

and

error,

I

had

developed

enough

knowledge

and

experience

over

the

years

to

teach

two

woodworking classes and a furniture design course at Bellingham Technical College from 2002 to 2009.

Design Process

For

me,

the

design

process

is

one

of

the

most

enjoyable

aspects

of

woodworking

because

it

combines

customer

relations

and

technical

wizardry.

I

enjoy

sitting

down

with

clients,

getting

to

know

their

likes

and

dislikes, their dreams and desires. Most of all, I enjoy playing my part as their wishes become reality.

There

are

a

number

of

considerations

to

be

aware

of

when

designing

a

piece

of

custom

furniture,

not

the

least

of

which

is

price.

It

is

important

to

discuss

the

client’s

budget

early

on

at

this

stage

since

custom

furniture

is

expensive

for

obvious

reasons.

If

cost

is

a

major

issue,

I

sometimes

suggest

that

a

client

purchase

retail

if

what

they

are

looking

for

is

available.

But

owning

a

one-of-a-kind

piece

of

custom

furniture

has

great

appeal

to

most

of

my

clients.

Where

a

piece

will

be

displayed,

the

style

of

the

surrounding

furniture

and

the

color

scheme

of

the

room

also

play

a

part

in

the

design

process.

Although

more

homes

are

furnished

in

a

more

eclectic

style

today,

there

are

those

who

prefer

certain

themes

in

individual

rooms.

I

don’t

do

reproductions,

per

se,

but

I

do

call

upon

certain

styles

to

guide

my

designs

where

appropriate.

Materials

selection,

joinery

techniques

and

finish

can

also

effect

the

design

and

price.

These

details

are

worked

out

with

the

client

during

the

design

process

if

they

are

committed

to

a

custom

piece of quality furniture.

Methods and Techniques

I

have

profound

respect

for

those

woodworking

purists

who

shun

power

tools

for

hand

work.

But

for

reasons

of

expediency

and

cost

to

the

client,

I

try

to

find

a

balance

between

machines

and

hand

tools. I

use

stationary

power

tools

for

cutting,

drilling,

planing,

and

jointing

the

lumber,

and

a

combination

of

power

and

hand

tools

for

joinery

and finishing.

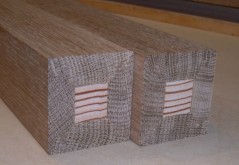

I

am

partial

to

mortise

and

tenon

rather

than

dowel

joinery,

frame

and

panel

rather

than

plywood,

and

dovetails

rather

than

rabbets.

Some

applications

may

be

interchangeable

in

some

cases,

but

where

the

choice

affects

the

structural

integrity

of

the

piece,

I

cannot

sacrifice

quality

for

cost.

When

designing

a

piece,

I

apprise

the

client of the options where there are options, and where there are not.

Since

my

shop

is

small,

I

prefer

to

devote

100%

of

my

energies

into

one

project

at

a

time.

But

I

am

able

to

work

on

a

couple

of

projects

at

a

time,

depending

on

the

pieces.

I

have

to

be

creative

at

times

trying

to

find

room

to

assemble

a

20

foot

long

by

5

foot

wide

conference

table,

for

instance.

Large

pieces

are

designed

and

built

in

sections

for ease of transport, and a complete set of assembly instructions are included in each shipment.

The

type

of

finish

used

on

a

piece

depends

on

the

look

desired,

how

the

piece

will

be

used

and

where

it

will

be

displayed.

I

use

combinations

of

oil

and

paste

wax

in

situations

of

light

wear,

lacquer

for

medium,

and

varnish

for

heavy

use

areas.

I

try

to

avoid

staining

at

all

costs.

Staining

dulls

the

inner

light

of

natural

wood

and

mutes

the

myriad

color

variations

within

each

board.

Instead,

I

prefer

to

choose

boards

for

their

color

and

grain

orientation

and

arrange

them

to

create

balance

of

the

piece

overall. These considerations and other choices are decided upon during the design process and are determined on an individual basis.

All

in

all,

my

methods

and

techniques

are

custom

designed

to

suit

the

project,

available

technology,

and

the

client’s

tastes

and

budget.

Although

I

have

my

preferences,

I

will

not

sacrifice

structural

or

design

integrity

for

price.

I

want

to

put

out

a

quality

product

at

an

affordable price. This has been the cornerstone of my business since 1977.

I hope you can appreciate the kind of work I do and give me the opportunity to help your dreams become reality.

Stribling Design Woodworks

2724 Michigan St. Bellingham, WA 98226 360 671-3739

Stribling Design Woodworks

2724 Michigan St. Bellingham, WA 98226 360 671-3739

All About Stribling Design Woodworks

Stribling

Design

Woodworks

is

a

small,

one

man

shop

specializing

in

custom

designed

and

fabricated

furniture

and

fine

woodworking.

Although

some

designs

have

been

created

in

limited

production

runs,

the

bulk

of

my

business

comes

from

customers

who

require

custom,

one-

of-a-kind

pieces.

Designed

and

handcrafted

to

meet

the

needs

and

tastes

of

each

client,

the

finished

products

have

become

treasured,

first

generation heirlooms.

Since

my

first

commissioned

piece

in

1977,

woodworking

had

been

a

part

time

venture,

until

1988

when

the

volume

of

orders

enabled

me

to

design

and

build

custom

furniture

full

time.

Mostly

self-taught

through

books,

magazines

and

trial

and

error,

I

had

developed

enough

knowledge

and

experience

over

the

years

to

teach

two

woodworking

classes

and

a

furniture

design

course

at

Bellingham Technical College from 2002 to 2009.

Design Process

For

me,

the

design

process

is

one

of

the

most

enjoyable

aspects

of

woodworking

because

it

combines

customer

relations

and

technical

wizardry.

I

enjoy

sitting

down

with

clients,

getting

to

know

their

likes

and

dislikes,

their

dreams

and

desires.

Most

of

all,

I

enjoy

playing

my

part as their wishes become reality.

There

are

a

number

of

considerations

to

be

aware

of

when

designing

a

piece

of

custom

furniture,

not

the

least

of

which

is

price.

It

is

important

to

discuss

the

client’s

budget

early

on

at

this

stage

since

custom

furniture

is

expensive

for

obvious

reasons.

If

cost

is

a

major

issue,

I

sometimes

suggest

that

a

client

purchase

retail

if

what

they

are

looking

for

is

available.

But

owning

a

one-

of-a-kind

piece

of

custom

furniture

has

great

appeal

to

most

of

my

clients.

Where

a

piece

will

be

displayed,

the

style

of

the

surrounding

furniture

and

the

color

scheme

of

the

room

also

play

a

part

in

the

design

process.

Although

more

homes

are

furnished

in

a

more

eclectic

style

today,

there

are

those

who

prefer

certain

themes

in

individual

rooms.

I

don’t

do

reproductions,

per

se,

but

I

do

call

upon

certain

styles

to

guide

my

designs

where

appropriate.

Materials

selection,

joinery

techniques

and

finish

can

also

effect

the

design

and

price.

These

details

are

worked

out

with

the

client

during

the

design

process

if

they

are

committed

to

a

custom

piece

of quality furniture.

Methods and Techniques

I

have

profound

respect

for

those

woodworking

purists

who

shun

power

tools

for

hand

work.

But

for

reasons

of

expediency

and

cost

to

the

client,

I

try

to

find

a

balance

between

machines

and

hand

tools. I

use

stationary

power

tools

for

cutting,

drilling,

planing,

and

jointing

the

lumber,

and

a

combination

of

power

and

hand tools for joinery and finishing.

I

am

partial

to

mortise

and

tenon

rather

than

dowel

joinery,

frame

and

panel

rather

than

plywood,

and

dovetails

rather

than

rabbets.

Some

applications

may

be

interchangeable

in

some

cases,

but

where

the

choice

affects

the

structural

integrity

of

the

piece,

I

cannot

sacrifice

quality

for

cost.

When

designing

a

piece,

I

apprise

the

client

of

the

options

where

there

are

options,

and

where

there

are not.

Since

my

shop

is

small,

I

prefer

to

devote

100%

of

my

energies

into

one

project

at

a

time.

But

I

am

able

to

work

on

a

couple

of

projects

at

a

time,

depending

on

the

pieces.

I

have

to

be

creative

at

times

trying

to

find

room

to

assemble

a

20

foot

long

by

5

foot

wide

conference

table,

for

instance.

Large

pieces

are

designed

and

built

in

sections

for

ease

of

transport,

and

a

complete

set of assembly instructions are included in each shipment.

The

type

of

finish

used

on

a

piece

depends

on

the

look

desired,

how

the

piece

will

be

used

and

where

it

will

be

displayed.

I

use

combinations

of

oil

and

paste

wax

in

situations

of

light

wear,

lacquer

for

medium,

and

varnish

for

heavy

use

areas.

I

try

to

avoid

staining

at

all

costs.

Staining

dulls

the

inner

light

of

natural

wood

and

mutes

the

myriad

color

variations

within

each

board.

Instead,

I

prefer

to

choose

boards

for

their

color

and

grain

orientation

and

arrange

them

to

create

balance

of

the

piece

overall.

These

considerations

and

other

choices

are

decided

upon

during

the

design

process

and

are

determined

on

an

individual

basis.

All

in

all,

my

methods

and

techniques

are

custom

designed

to

suit

the

project,

available

technology,

and

the

client’s

tastes

and

budget.

Although

I

have

my

preferences,

I

will

not

sacrifice

structural

or

design

integrity

for

price.

I

want

to

put

out

a

quality

product

at

an

affordable

price.

This

has

been

the

cornerstone

of

my business since 1977.

I

hope

you

can

appreciate

the

kind

of

work

I

do

and

give

me

the opportunity to help your dreams become reality.